STANDARD

ANSI/ISEA 105-2016

American National Standard for Performance and Classification for Heat Resistant Gloves

ANSI/ISEA 105-2016 establishes performance levels, testing and classification for gloves designed to provide heat and/or flame resistance while performing occupational tasks.

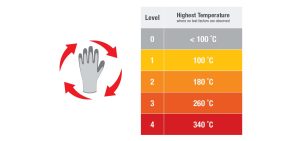

The standard, based on ASTM F1358-08 for ignition resistance and burning behavior; ISO 17493:2000 for heat degradation resistance; and ASTM F1060-08 for conductive heat resistance, tests the glove’s resistance to heat and flame. Gloves are classified according to their performance when tested in accordance to the specified test method.

Conductive Heat Resistance

When testing using the ASTM F1060-08 standard, the classification of a glove’s conductive heat resistance shall be based on the surface temperature at which both the time-to-second degree burn is equal to or greater than 15 seconds, and the alarm time is greater than 4 seconds. The alarm time is the difference between the measured time-to-second degree burn and the time-to-pain in accordance with ASTM F1060.

Testing (ASTM F1060-08)

A rectangular sample of the glove material is placed on a hot plate heated to selected test temperatures, after which a weighted sensor is immediately placed on top. This measures the heat energy transferred through the material and absorbed by the sensor, and then related to the energies required to cause the sensation of pain and a second degree burn injury. The time to the second degree burn, and the difference between that time and the alarm time (pain sensation) are reported.

Recommended test methods not covered in the above standards include Radiant Heat Insulation (ASTM F1939-08) which measures a glove’s resistance to radiant heat transfer; and Combined Radiant and Convective Heat Insulation (ISO 17492:2003) which measures thermal protective performance for exposure to both radiant heat and flame.

Ignition and Burning Resistance

In testing for ignition resistance and burning resistance to ASTM F1358, the glove material is first exposed to flame and the time to flame extinction is determined. Testing is performed at either 3 or 12 seconds of flame exposure, which is then subtracted to determine the after-flame time. If there is no ignition at 3 seconds, the sample is then tested at the 12 second exposure. As it is difficult to determine if ignition has occurred when the material is exposed to the flame, ignition time can only be 3 seconds, 12 seconds, or no ignition. Burn time is based on the materials behavior after exposure.

Heat Degradation Resistance

When testing using the ISO 17493:2000 standard, heat degradation resistance classification shall be at the temperature where there is no evidence of charring, ignition, melting, dripping, and separation, and shrinkage is not greater than 5% when tested on a whole glove. Higher temperatures reported by this method indicate gloves having greater heat degradation resistance.

Testing (ISO 17493:2000)

Whole gloves are filled with vermiculite and suspended in a forced air-circulating oven for 5 minutes at selected test temperatures, after which the glove is inspected for signs of charring, ignition, melting, dripping or separation. The glove is also measured for shrinkage. The highest temperature where no heat degradation or shrinkage over 5% is reported is used to classify glove performance.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.