STANDARD

EN 374-1:2016

European Standard for Protective Gloves against Dangerous Chemicals and Micro-organisms

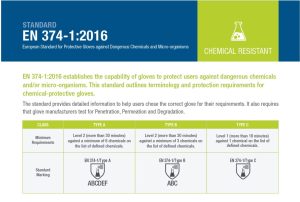

EN 374-1:2016 establishes the capability of gloves to protect users against dangerous chemicals and/or micro-organisms. This standard outlines terminology and protection requirements for chemical-protective gloves.

The standard provides detailed information to help users chose the correct glove for their requirements. It also requires that glove manufacturers test for Penetration, Permeation and Degradation.

Penetration

Penetration is the movement of a chemical and/or micro-organism through porous materials, seams, pinholes, or other imperfections in a protective glove material at a non-molecular level. Testing measures the time taken for a chemical to break through the glove material and come into contact with the skin. A glove shall not leak when tested with an air leak and water leak test, and shall be tested and inspected in compliance with standard EN 374-2:2014.

Permeation

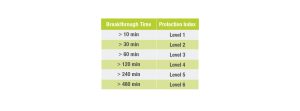

Permeation is the movement of a chemical and/or micro-organism through the protective glove material on a molecular level, as individual molecules of the chemical pass between the molecules of the protective glove material. Measuring the breakthrough times, or the time taken for the chemical to come in contact with the skin, requires three samples taken from the palm of the glove. Each of the 18 chemicals tested are classified in terms of breakthrough time performance level 0 to 6. Based on permeation performance, gloves are separated into three classification types– Type A, Type B or Type C. If the length of the chemical protective glove is 40 cm or more, the cuff area must also be tested for permeation.

Degradation

Degradation is the change in one or more of the properties of the glove material when exposed to contact with a chemical. Signs of degradation on glove material can include hardening, softening, flaking, swelling, disintegration, brittleness, colour change, and changes in size, shape or appearance. Degradation testing is done in accordance with standard EN 374-4:2019, testing the change of puncture resistance after contact for all claimed chemicals. If the length of the chemical protective glove is 40 cm or more, the cuff area must also be tested for degradation.

For the latest safety standards, classifications, testing criteria and ratings information, please refer to the appropriate governing body or association. Information contained in this document is subject to change without notice. As BDG® cannot control or anticipate the conditions under which a product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, Bob Dale Gloves and Imports Ltd., and/or its affiliates, employees or representatives will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this sheet. No express or implied warranties are given other than those implied mandatory by law. BDG® products are not cut and puncture proof. Do not use with moving blades, tools or serrated blades.